What are the Advantages and Unique Features of Pad Printing?

Pad printing opens up new possibilities which were not available with traditional printing processes, or which could be exploited only with great effort. To some extent, pad printing also replaces other decorating processes, such as screen printing, labeling and hot stamping. The form used for pad printing is a plate of etched steel or washed out photopolymer. As with intaglio, the image printing elements are contained (etched) in the non-printing surface. During a printing operation, the plate is covered with ink, the excess is doctored from the surface of the plate, and the ink for the print remains in the depressions. A soft, elastic pad then transfers the ink from the depressions onto the substrate. The areas of application are so extensive that dozens of pad printed articles are encountered every day in the form of commercial items, such as lighters, ball pens and toys, as well as housings, switches, keys, knobs and buttons in the automotive and electronics industries.

Pad Printing Buyer’s Guide

Pad Printing Machine are available in a great variety of sizes, versions and with different drives. The printing pad, cliche and ink system are the elements common to all types. Differences are seen in the physical structure and layout of the components, as well as the movement patterns.

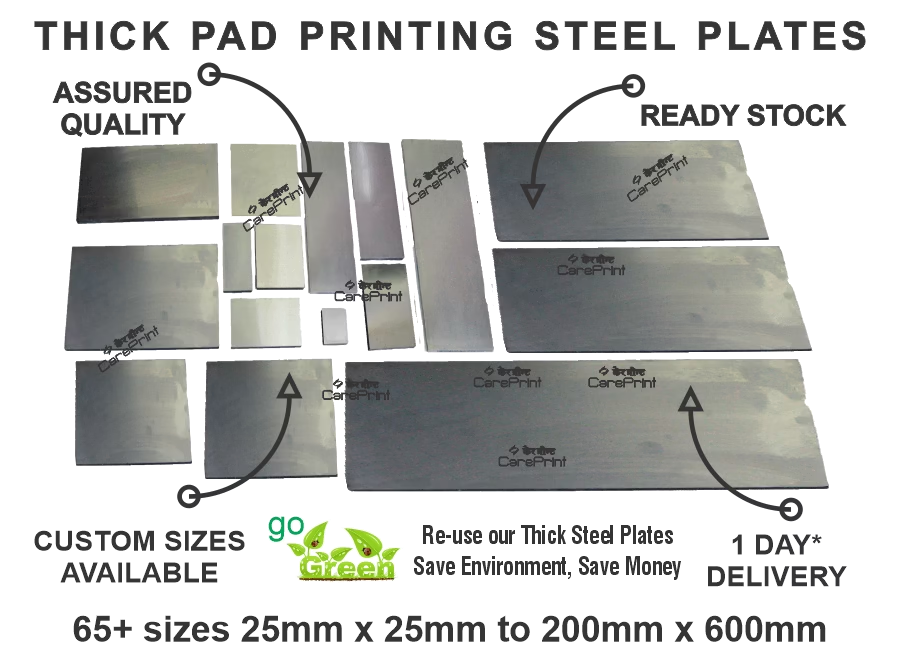

Closed Cup Machine or Open Ink Well Machine – Plates No Problem!!! We always have a ready stock of large variety of different sizes of Cliché Plates or Tampon Plates. We have around 65+ sizes of plates ready for the customer. Our Steel clichés are especially suited to high quantity printing.

The pad receives the motif from the cliche, transfers the ink film to the substrate and deposits it there. The pad must be constructed so that it is pliable, but guarantees transfer of the motif without smudges or blurring.Printing pads are made of silicone rubber and produced as stamps in a wide array of shapes, hardnesses and qualities.

To achieve optimal print quality, special pad printing inks must be used. These inks display very highly concentrated pigmentation, as only very small quantities of ink are transferred in the pad printing process.

Plastics such as polyethylene, polypropylene and polythene will not accept print in their natural state. For a plastic to accept ink, it is necessary for it to be wettable by that ink. For this to be so, the surface tension or surface energy, measured in dynes/cm, must be greater than the surface tension (energy) of the ink.

With our vast experience of manufacturing Pad Printing Machines, Pad Printing Plates, Silicone Rubber Pads and Fixtures we have listed all potential solutions related to Pad Printing for achieving best possible printing result..