We bring you the best Pad Printing Plate Buyer’s Guide which will enlighten you with different types of Plates

Plates are selected on the basis of the Pad Printing Machine supported

The cliche is the carrier of the print motif. Varying types of cliches are used depending on the desired print quality and quantity. The motif is recessed, etched into or washed out of the cliche. In order to assure smooth fitting and printing, the motif should be at a distance of at least 25 mm (1 inch) from the outer edge, and centered on the plate. In the case of long or fine lines, the motif must be at an angle of approx. 5° to 15° to the blade track in order for the doctor blade not to dip too low and scoop out too much ink. Numerous trials have shown that an etching depth of 25 µm is optimal for pad printing. Since the pad can only transfer a limited quantity of ink, a greater depth is pointless. At an etching depth of 25 µm, the pad only picks up an ink film of 12 µm. The rest remains in the depressions of the cliche. Because the ink film consists of approx. 40 % to 60 % thinner, which evaporates during the transfer and drying, the actual thickness of the ink film left on the substrate comes to around 5 µm – 8 µm, in some cases, as little as 2 µm. As an exception to the above statement, very fine fonts are etched at approx. 15 µm, and very large motifs, at approx. 30 µm. For very large surfaces, the dip of the doctor blade can be avoided by additionally copying a fine screen into the motif.

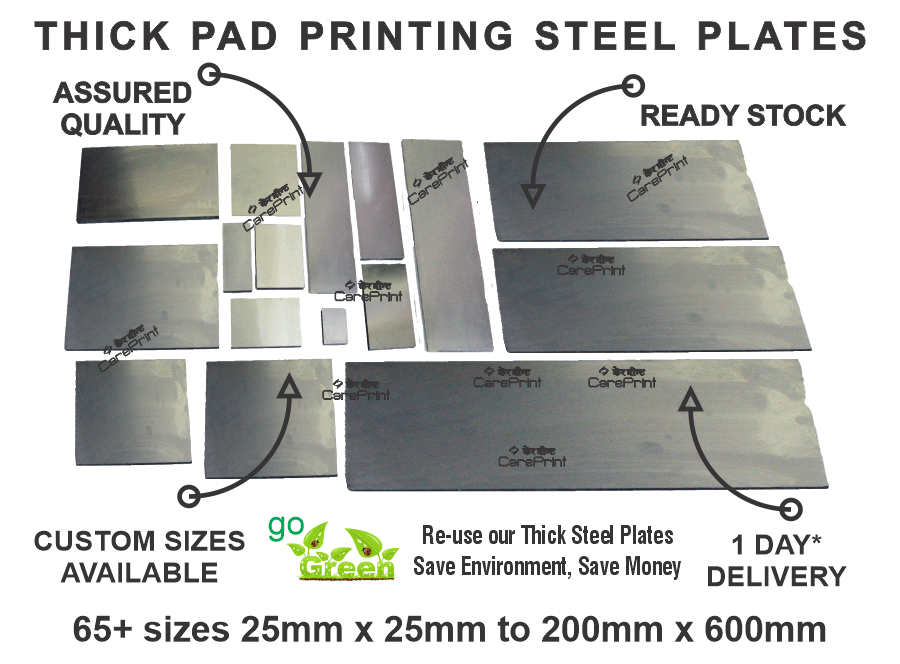

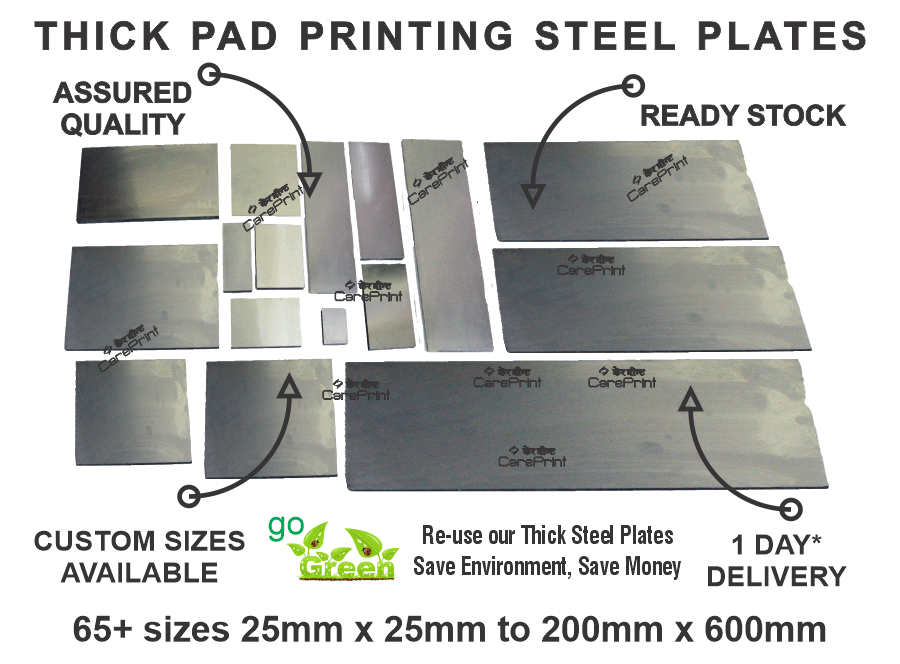

1: THICK STEEL PAD PRINTING PLATE

This classic cliche is produced from special high-grade, abrasion-proof steel. Its area of application is found primarily in the industrial sector. Steel clichés are especially suited to high quantity printing runs and closed ink systems. The quality of these clichés is unequaled. This is evident from their absolute sharpness of contour, multi-stage etching, utilization of screens of all types, very fine surface, low susceptibility to physical damage and consistency in high quantity printing runs. The number of prints which can be achieved using this cliche comes to at least 1,000,000 doctoring operations.

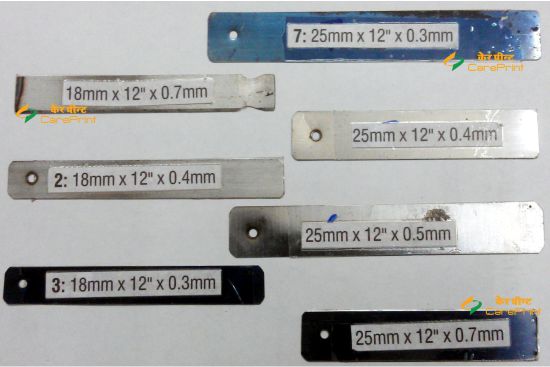

2: THIN STEEL PAD PRINTING PLATE

This is a strip of spring steel, 0.5 mm (0.02 in.) in thickness, with a very fine surface, and a hardness ranging between approx. 48 and 54 Rockwell. In the press, the steel strip is held in the ink well by a metal plate. The advantage of steel strip cliches over photopolymer ones is that within one cliche, sections of a motif can be screened while other sections are not. As well, etching can be done in stages, i.e., certain portions of a motif can be etched more or less deeply than others. The quantity of prints which can be made depends on the type of press used and the settings, as a steel strip cliche is somewhat softer than a doctor blade. In practice, the serviceability allows between 20,000 and 100,000 printing runs.

3: ALUMINIUM PAD PRINTING PLATE

This type of plate is developed by TAMPOPRINT GERMANY.

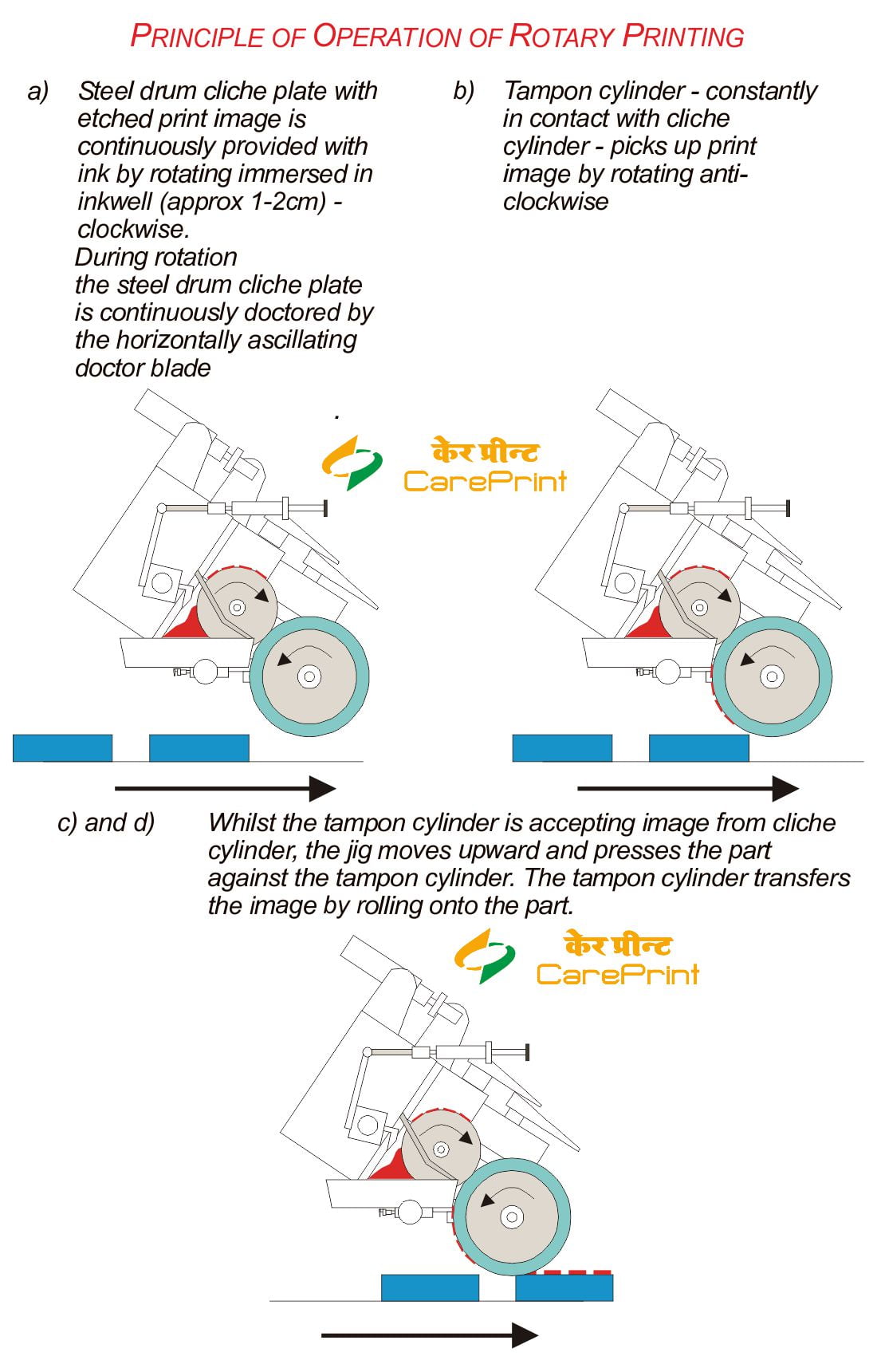

4: STEEL ROLLER PAD PRINTING PLATE

For rotary presses, steel rollers are necessary. Since the printing may sometimes be done in a scope of 360°, the film montage and production of the rollers is very expensive. Special etching equipment is also required.

5: CERAMIC PAD PRINTING PLATE

This type of is also developed by TAMPOPRINT GERMANY, the biggest advantage of this type of plate is huge number of imperssions obtained as the plate is of ceamic materic and never gets rusted or worn out

6: PHOTO-POLYMER PAD PRINTING PLATE

Photopolymer cliches consist of a UV light sensitive layer of plastic which, if necessary, is bonded to a metal carrier by an adhesive coating. Single as well as double-layer materials are used for photopolymer cliches. With the latterlayer of approx. 25 µm is generally carried off during the developing process. These cliches are unsuited to screened motifs. The thickness of the single-layer material is up to 400 µm, and the etching depth is controlled by the exposure and the use of a screen.The number of prints which can be obtained using this cliches lies in the range of some 10.000 doctoring operations. Under optimal conditions runs up to 100.000 prints are attainable. Areas of use for this type of cliche include (progressive) proofs, pre-series runs and smaller jobs.

With over 200+ Customers and counting, Careprint is the most complete and trusted company for Pad Printing and Screen Printing products like Pad Printing Machine, Pad Printing Plates, Pad Printing Silicone Pads, Jig Fixtures, Screen Printing Machine, Stencils, Squeegees, Emulsion

Great benefits from Buying Our Pad Printing Steel Plates / Cliche

Other Manufacturers

Pad Printing 101.

The ultimate Purchase Guide which will advice you on how to Buy, maintain, re-use and safely discard after use our Pad Printing Plates, Silicone Pads, Inks.

Pad Printing Machine Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.

Pad Printing Plate Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.

Pad Printing Silicone Pad Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.

Pad Printing Ink Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.