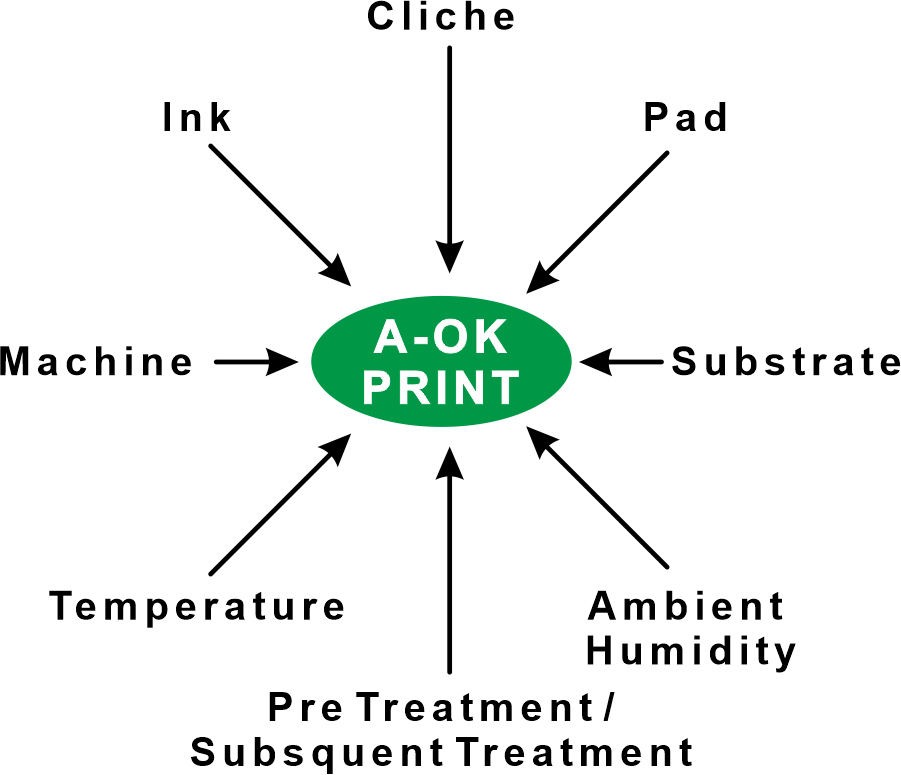

What Factors influence obtaining Quality Print?

From the facts mentioned so far, it becomes evident that the result of printing is influenced by a multitude of factors. Experience shows that the root cause of a faulty print is virtually never to be found in the mechanics of the printing press.

Defects in the Pad Printing Machine itself are nearly always obvious, clearly definable and can be remedied by the technicians of the manufacturer. Hence, this issue can be ignored. To eliminate problems connected with printing, it is of greatest importance to describe deficiencies in as detailed a way as possible.

Any Pad Printing technician has difficulties on the telephone when a customer makes statements which are only general in nature. Not even the best technician can be of assistance when simply told “the press won’t print” or “the quality of the print is poor.”

Sources of Deficiency in getting Optimal Printing Results

Deficiencies most commonly found in printed material:

– no opacity

– misregister

– motif distorted

– blurring

– poor leveling of ink

– problematic overprintability in multi color prints

– color does not correspond with artwork

– spiderweb effect on contours

– screen dots are visible/are not visible

– fine lines run together

– large areas not completely covered

– small bubbles (pinholes) visible

– motif smudged

– ink does not adhere to substrate

– desired grade of gloss cannot be achieved

During printing operation:

– pad does not pick up ink

– no deposit or only partial deposit of ink by pad

A number of additional problems arise, which are, however, very particular to the individual areas:

Pre-operational deficiencies, e.g.:

– inadequate pre-treatment

– no or only partial deposit of ink on substrate

Post-operational deficiencies, e.g.:

– ink/color turns after some time

– ink cannot be lacquered

– ink does not adhere to substrate

Containment of Deficiencies

In order for any problems which arise to be contained quickly, the individual components (e.g., substrate, pad, cliche and ink) should be systematically changed or replaced.

The settings of the Pad Printing Machine and the ambient conditions (humidity!) should be checked. Making individual sample prints at a higher or lower printing speed or blowing on the pad can also be helpful.

Description of Problems and Proposed Solutions

Potential Problems in Printing – Description of Problems and Proposed Solutions

| Problem | Solution |

|---|---|

| 1. Too thick. | 1. Add thinner. |

| 2. Dried out. | 2. Clean cliche with thinner. |

| 3. Wrong thinner. | 3. Use slower thinner or one suited to ink system. |

| Problem | Solution |

|---|---|

| 1. Insufficient etching depth. | 1. Produce new cliche with greater etching depth. |

| 2. Wrong screen ruling. | 2. Test new cliche with different fineness of halftone screen. |

| 3. Surface physically damaged. | 3. Use new cliche. |

| Problem | Solution |

|---|---|

| 1. Too flat. | 1. Use more tapered pad shape. |

| 2. Surface roughened. | 2. Replace pad. |

| 3. Pad swollen. | 3. Blow air on pad. |

| 4. Surface too oily | 4. Clean pad (several times) or replace. |

| Problem | Solution |

|---|---|

| Problem | Solution |

|---|---|

| 1. Too thick. | 1. Add thinner. |

| 2. Dried out. | 2. Clean cliche with thinner. |

If ink pulls on pad fibers during pickup, it is too thick and needs thinning.

Potential Problems in Printing – Description of Problems and Proposed Solutions

| Problem | Solution |

|---|---|

| 1. Dried out on pad. | 1. Use slower thinner. |

| 2. Too wet on pad,not tacky. | 2. Use faster thinner. |

| Problem | Solution |

|---|---|

| 1. Insufficient etching depth. | 1. Produce new cliche with greater etching depth. |

| 2. Etched too deeply. | 2. Produce new cliche with shal-lower etching depth. |

| 3. Wrong screen ruling. | 3. Use new cliche with different fineness of half-tone screen. |

| Problem | Solution |

|---|---|

| 1. Wrong shape pad. | 1. Use more tapered pad shape. |

| 2. Surface rough-ened. | 2. Replace pad. |

| Problem | Solution |

|---|---|

| 1. Soiled surface(grease, oil, per-spiration, mold release agents..). | 1. Pre-clean objects. |

| 2. Surface insufficiently pre-treated (polyolefins). | 2. Check pre-treat-ment, repeat as required. |

| Problem | Solution |

|---|---|

| 1. Print speed set-ting too slow. | 1. Maintain uniform cycle time. |

| 2. High ambient(room) temperature. | 2. Optimal room temperature is 18 °C – 20 °C or 65 °F – 68 °F |

ncomplete or spotty deposit of ink by pad is referred to as “splitting.” It plays a minor role in a continuously running process. The problem only arises when cycle times fluctuate or after short breaks. The pad deposits the dried ink all at one time, producing an inconsistent image. Using fast thinners will decrease ink build-up and improve ink deposition.

Potential Problems in Printing – Description of Problems and Proposed Solutions

| Problem | Solution |

|---|---|

| 1. Too thin. | 1. Reduce amount of thinner. |

| 2. Transparent ink. | 2. Use opaque color shade. |

| 3. Wrong ink system. | 3. Use pad printing ink . |

| 4. Scanty ink transfer. | 4. Locate defect in cliché or pad. |

| Problem | Solution |

|---|---|

| 1. Insufficient etching depth. | 1. Produce new cliche with greater etching depth. |

| 2. Areas not screened. | 2. Screen area. |

| 3. Areas not slanted. | 3. Slant areas. |

| 4. Wrong cliche type. | 4. Use cliche which allows screen to be etched with it. |

| 5. Wrong screen ruling. | 5. Test new cliche with different fineness of half-tone screen. |

| Problem | Solution |

|---|---|

| 1. Too flat. | 1. Use more tapered pad shape. |

| 2. Porous surface. | 2. Replace pad. |

| 3. Too soft. | 3. Use harder pad. |

| Problem | Solution |

|---|---|

| 1. Soiled surface. | 1. Clean surface with alcohol. |

| 2. Dark substrate color. | 2. Double print. |

| 3. Surface too rough. | 3. Use harder, more tapered pad. |

| 4. Stress cracks (esp. on injection molded parts). | 4. Use milder ink/thinner system or quick drying ink/thinner to avoid any dissolution of substrate. |

| Problem | Solution |

|---|---|

| 1. Soiling from greasy residues on accessories(auxiliaries). | 1. Clean cliche,doctor blade, etc.before installing. |

| 2. Doctor blade sags. | 2. Use harder or thicker doctor blade (or see cliche points 2 and 3). |

This problem very often occurs in pad printing, and cannot always be solved satisfactorily. Due to the low degree of ink transfer in pad printing, 100 % opacity cannot be achieved on many objects with only a single printing, especially in the case of dark substrates. Increased hiding power can be attained by double or triple printing or preprinting with white.

Potential Problems in Printing – Description of Problems and Proposed Solutions

| Problem | Solution |

|---|---|

| Problem | Solution |

|---|---|

| 1. Individual motifs not correctly aligned. | 1. If motifs are all on one cliche,film must be cor-rected and new cliche must be produced. |

| Problem | Solution |

|---|---|

| 1. Pads mounted off center. | 1. Readjust pad. |

| 2. Pads not same shape. | 2. Replace pads with ones of correct shape. |

| 3. Pads not of same hardness. | 3. All pads should be of same Shore hardness. |

| 4. Head stroke not same over cliche and substrate material. | 4. Adjust head stroke. |

| Problem | Solution |

|---|---|

| 1. Material is pliable. | 1. Switch to different material. |

| Problem | Solution |

|---|---|

| 1. Jig not perfect. | 1. Check for play in jig, refabricate as needed. |

| 2. Carre,adjustable, or rotary indexing table inaccurate. | 2. Check indexing. |

| 3. Mounting screws not tight. | 3. Screws not properly tightened during initial setup; they become loose during printing operation. Tighten screws. |

The simplest way to contain these deficiencies is to produce a new cliche with precisely registered film.

Potential Problems in Printing – Description of Problems and Proposed Solutions

| Problem | Solution |

|---|---|

| Problem | Solution |

|---|---|

| 1. Motif not aligned with cliche. | 1. Hold film over finished print and compare; correct and pro- duce new cliche as needed. |

| Problem | Solution |

|---|---|

| 1. Wrong pad shape (pad too small). | 1. Test different pad shape. |

| 2. Too soft or too hard. | 2. Test other hard-nesses. |

| 3. Stroke force too great. | 3. Decrease the head stroke. |

| 4. Stroke force on cliche and sub-strate not equal. | 4. Correct the head stroke. |

| 5. Touch down at wrong point. | 5. Align pad to cor-rect contact area. |

| Problem | Solution |

|---|---|

| 1. Very soft/pliable. | 1. Cool objects before printing to harden mate-rial; inflate hol-low body. |

| 2. Material allows distortion. | 2. Switch to differ-ent material. |

| 3. Very deep recesses/depressions. | 3. Use pad assemblies or jigs which compensate for depressed areas; produce special pad as needed. |

| 4. Edges in proximity to motif. | 4. Use pad assemblies or jigs which compensate for depressed areas; produce special pad as needed. |

| Problem | Solution |

|---|---|

| 1. Unsuitable jig. | 1. Modify jig so that substrate is supported in all print/contact areas. |

| 2. Work piece mounted at wrong angle. | 2. Test correct angle using adjustable wedge. |

| 3. Jig too unstable. | 3. Produce new jig. |

Distortion means that a printed rectangle, for example, does not show any right-angled corners, and has more the shape of a cushion. Distortion occurs primarily in very curved motifs or in motifs which are in proximity to an edge of the area to be printed or of the substrate. It is often impossible to achieve a 100 % correction. It is possible to make a wraparound print, but improvements with this method are also limited.

Potential Problems in Printing – Description of Problems and Proposed Solutions

| Problem | Solution |

|---|---|

| 1. Too thick. | 1. Add thinner. |

| 2. Too thin. | 2. Use new ink. |

| 3. Too slow. | 3. Use faster thinner. |

| Problem | Solution |

|---|---|

| 1. Poor etching. | 1. Examine cliche with magnifying glass, produce new cliche as needed. |

| 2. Etching too deep. | 2. Produce new cliche with shallower etching depth. |

| 3. Wrong cliche type. | 3. Replace with correct cliche. |

| 4. Wrong screen ruling. | 4. Test new cliche with different fineness of halftone screen. |

| Problem | Solution |

|---|---|

| 1. Too soft. | 1. Use harder pad. |

| 2. Wrong shape. | 2. Test different shape. |

| Problem | Solution |

|---|---|

| 1. Soiled surface. | 1. Pre-clean with alcohol. |

| 2. Not free of distortion. | 2. Switch to different material. |

| 3. Great differences in height. | 3. Use pad assembly or special pad. |

| 4. Printing in proximity to edges. | 4. Jig should support substrate adjacent to edges, to prevent pad from extending over edge. |

| 5. Very structured surface. | 5. Use hard, pointed pad. |

| Problem | Solution |

|---|---|

| 1. Jig unstable. | 1. Refabricate jig. |

| 2. Fast cycle time with bulky pad. | 2. Reduce speed, adjust setting to delayed cycle in front position to prevent pad from wobbling during print stroke. |

Blurred print is understood as the indistinct, hazy reproduction of lines or letters. This deficiency is often confused with distortion.