We bring you the best Pad Printing Machine both the worlds, Open Ink-Well as well a Closed Cup.

Open Inkwell Pad Printing Machine versus Closed Cup Pad Printing Machine

Benefits of Open-Inkwell over Closed-Cup Machine

Benefits of Closed-Cup over Open Inkwell Machine

We bring you the best Pad Printing Machine both the worlds, Open Ink-Well as well a Closed Cup.

Open Inkwell Pad Printing Machine versus Closed Cup Pad Printing Machine

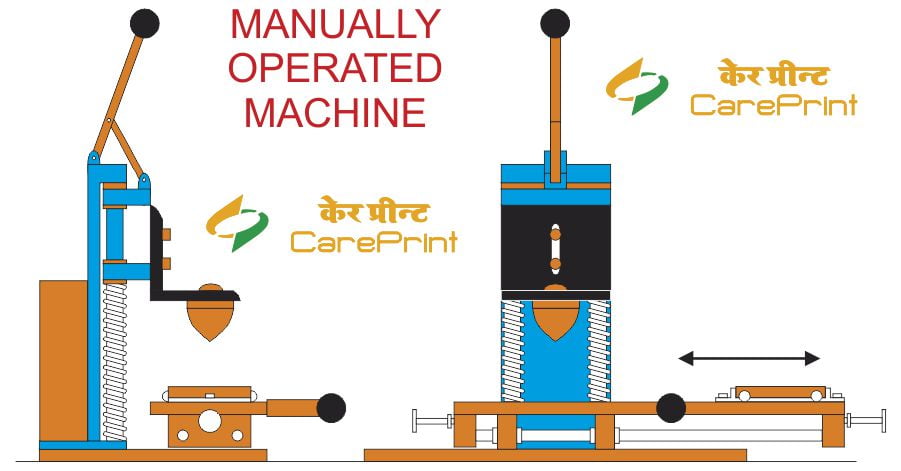

1: MANUAL PAD PRINTING MACHINE

The first machines were manually operated. Very high quality watch and instrument dials have been printed over the years using hand powered machines. Now the only reason for buying them is the initial cost.

They are not really entry level machines except where printing is carried out on a small scale. Print rates are very low and maintaining quality over a continuous run is extremely difficult.

A well engineered unit can be useful for proofing plates, pads, inks and designs as an alternative to taking a production machine off line.

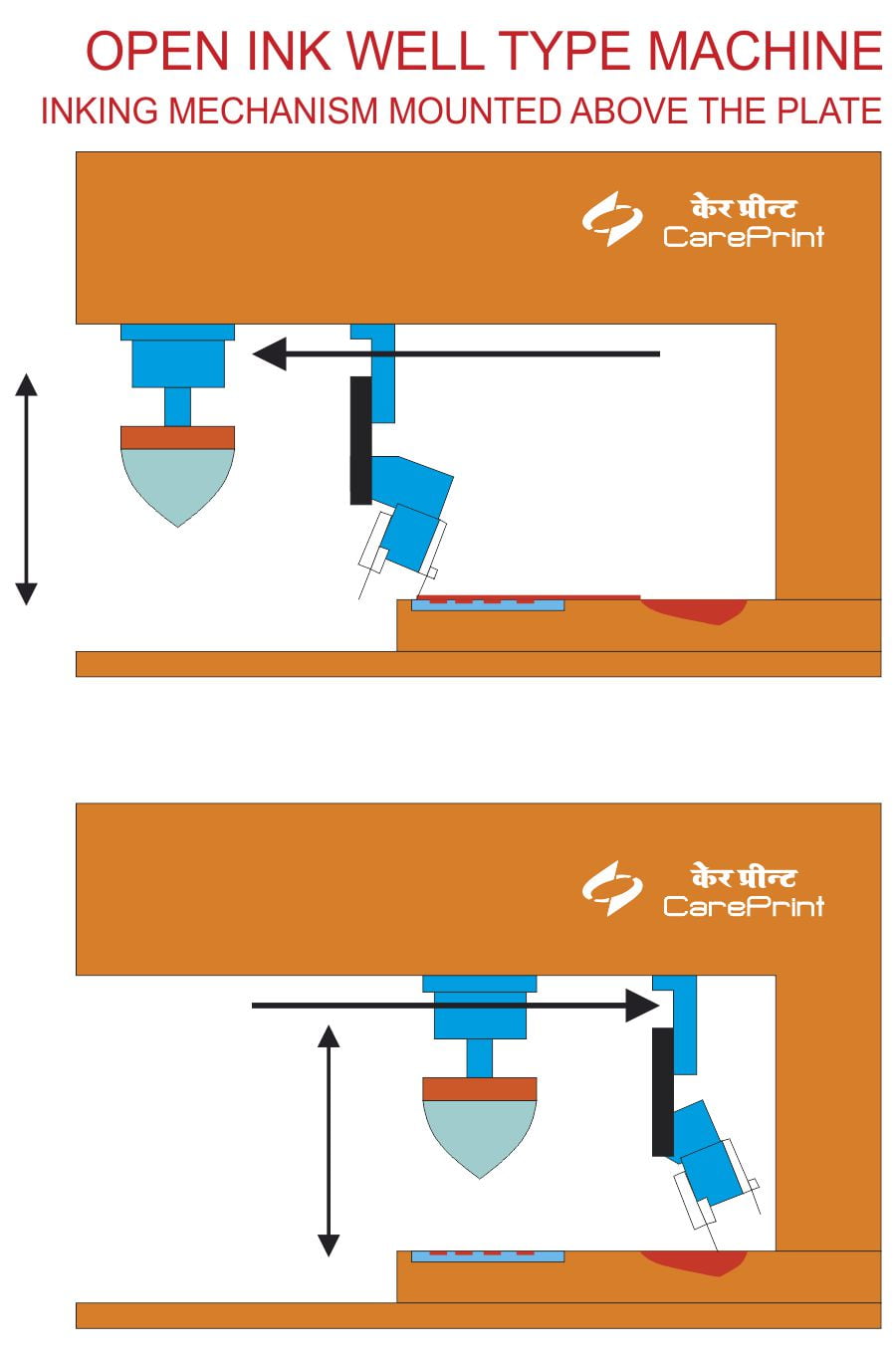

2: OPEN INKWELL PAD PRINTING MACHINE

There are many machines of this type out in the field as it was the original system designed in the late 1960′s early 1970′s that has been used as the basis of many clones. Original machines were mechanically operated giving little opportunity for adjustment of individual actions as the inking mechanism and pad horizontal action were tied together on the same drive. Adjusting the speed of the main drive motor controls the overall speed of the machine. Later more sophisticated mechanically driven machines gave greater flexibility of adjustment. This is a very robust system that is unaffected by fluctuations in air line pressure. It gives a smooth action and has been used extensively with larger machines working on long runs.

The concept has developed and a host of machines have been produced using electro pneumatics and even servo motor drives. PLC’s (Programmable Logic Controllers) can provide a wide range of sequencing options. Whatever the degree of sophistication the control of ink conditions is problematic due to the large surface area exposed to atmosphere. This can be ameliorated in different ways. Some manufacturers help reduce evaporation by shrouding the inking mechanism and ink well and others by using ink pumps and solvent addition systems.

Changeover of ink and plate can be carried out relatively quickly by removing the ink tray containing the plate and replacing it by another that has already been prepared. Consideration regarding the cost of spare ink trays must be given, as they can be very expensive. The ink tray can be designed to catch ink that spills over the front of the plate, thus keeping the machine cleaner

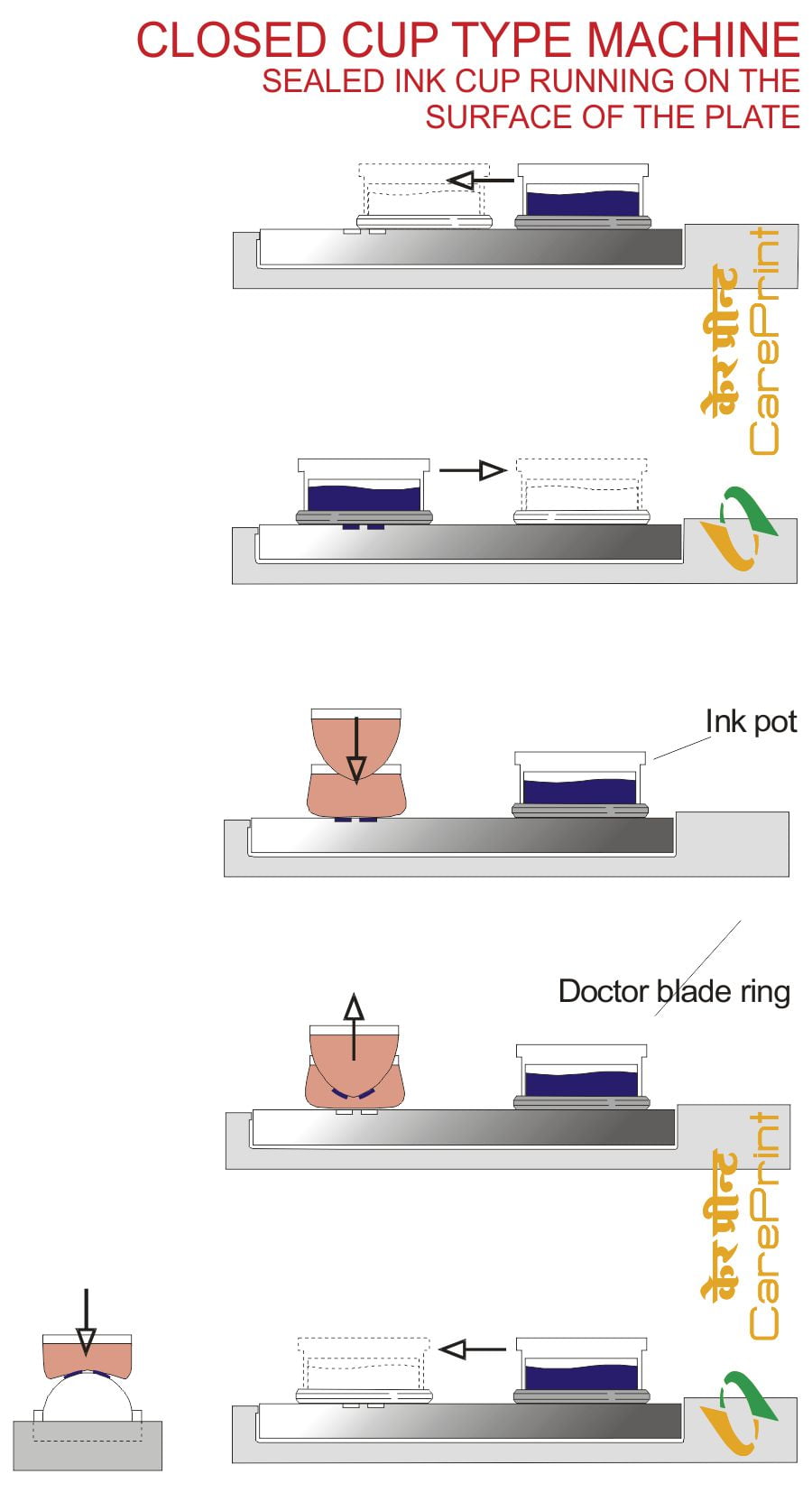

3: CLOSED CUP PAD PRINTING MACHINE

This system is considered by some to be the panacea to all Pad Printing ills, would that it was so. What is surprising is that this “New development†has been around for many years. A Swiss manufacturer of Pad Printing machines for the watch dial industry had a system 35 years ago! Although pretty basic it performed very well indeed.

The concept is to contain the ink in a cup that is turned upside down and the ink sealed in by pressing the cup down onto the plate. The cup not only holds the ink but when traversed over the plate acts as a doctor blade and leaves ink just in the etched areas on the plate.

The obvious advantage of the system is that solvent evaporation is reduced to a minimum. This allows much closer control of ink conditions resulting in the opportunity for reduced down time and partial unmanned operation. But, you say; “The machinery salesman told me it will run 24 hours 7 days a week 52 weeks a year.†Did he say what the print quality would be, how often do you have to top up with ink, how much will the plate wear, how long does the cup last, does the fact that certain ink corrode the plate matter, using two component inks is acceptable but don’t leave them for an extended period in the cup, with some systems it is better to keep the plates and cups as matched pairs. A question that must be asked is. “How much does a replacement cup costâ€. The answer can come as a surprise. £500 is not at all unusual. Fortunately if the damage to the cup is very slight it is possible to carefully hone the contact surface on a fine carborundum stone. Some cups can be re-machined at a quarter of the replacement costs. This all means the cups must be handled very carefully. The plate has to be twice the size of a conventional plate for a given image.

The issue of ink condition is crucial. With closed cup systems it is easy to have the attitude out of sight out of mind. Ink mixing is just as important as when you use an open ink well system. The mechanism of pad printing remains the same, evaporation of solvents being the governing characteristic. Solvents must be weighed into the ink and the mix is dependent on the image being printed. For example when fine detail is being printed the mix of solvent will contain a higher percentage of retarder; otherwise the ink will dry in the etching on the plate.

The most common problem is brought on by the impression that inks have an indefinite pot life when held in the closed cup. This is simply not so. Time and again users who are unhappy with print quality contact me. The solution often is to mix a new batch of ink and take out the old and replace it with new. If print quality is critical it is recommended that the ink is replaced once a day. When high volumes of ink hungry images are being printed regular topping up of the ink will be necessary. As long as correctly mixed inks are added ink condition will be maintained. Addition of solvents whilst in production is fraught with problems as the ink volumes are very low and one squirt can completely upset the solvent balance. Old ink that you remove from the cup should be disposed of and not mixed back in to the new ink. If print quality is not important then ink condition can have a much greater latitude.

Ambient conditions can still effect the performance of an ink but not to the same extent as machines with open ink wells. Differing ambient conditions will mean you will have to adjust the initial mix of ink to control solvent evaporation on the pad and in the etched plate.

Another problem that can occur is that some ink systems when used form a crust of dried ink around the edge of the cup. This crust will drag lines of ink across the image and ruin the print. Ink manufacturers have developed inks that overcome this problem so if your current supplier cannot solve it consider another supplier.

With closed cup systems plates generally have to be twice the size of open ink well systems. If you have a lot of plates this can be a substantial cost increase. Ideally the surface finish of the plate needs to be better than when it is cleared with a conventional doctor blade. The doctoring characteristics of the cup depend on the contact surface, machined from solid, spring steel or ceramic. This is allied to the bearing and clamping mechanism. There is no such thing as a cheap system. The cheaper it is the more expensive it is to run.

At times like these I would love to be able to give you my recommendations as to which manufacturer had the best combination but I have to remain impartial. By the very nature of these cups plate wear can be a problem. With steel harder flatter plates will be more effective.

Photopolymer plates are best used with cups that have ceramic rings. These rings are very flat and run well on the photopolymer material. Different photopolymer materials will perform better or worse and you will need to experiment. Broadly the harder materials are better not just from a wear point of view but also as regards to print quality. Multicolour machines are common place. The quality of engineering will determine the effectiveness of the system. Some manufacturers can offer either sealed ink cup or open inking mechanisms on the same basic machine. Later in this article I show the use of sealed ink cups in sophisticated CNC controlled equipment for multicolour printing.

As mentioned above ink cups have different constructions. The simplest is machined from solid metal. Normally hardened steel. The second type has a ribbon steel contact surface that can be replaced when worn. The third is a metal cup with a ceramic contact surface attached to the metal. This gives a very good life but is more expensive than the conventional cup. To achieve maximum life out of any system minimum pressure must be applied and the cup should be mounted on a stable bearing. Any tendency for the cup to rock will cause uneven wear and a consequential film of ink on the plate, which is transferred by the pad. Some manufacturers rotate the cup during the machine cycle can overcome this. Some systems use internal magnets to hold the cup onto the plate this appears to work very well. Be careful that the pigments in the ink are not effected by magnetism, if so they collect around the magnets and they are virtually impossible to use.

There is no doubt that the system is being refined and the use of larger cups is increasing the print area. Four colour machines with ink cup diameters of 210 mm are now available along with six colour machines with 150 mm cups.

The use of the sealed ink system is becoming more important as the effects of legislation require a much reduced level of solvents in the working environment and expelled into the atmosphere. Machines will either have cups that move backwards and forwards and the plate remains stationary or stationary cups and moving plates. The first system is normally used for larger images at slower speeds whereas the second is for higher speed printing of smaller images. There are exceptions. Whether a closed cup or open ink trough is used the same systems can apply. The moving plate with a single plane pad movement provides a cost saving for the machine supplier because there is one less actuation on the machine. From the users point of view as the pad only has to move in the vertical plane there is less vibration on the pad and the machine can cycle faster. This system is used with high speed coding machines. Here a small plate is used with a sealed ink cup.

Larger machines with plate areas of 200 mm by 450 mm have been produced using this method but they need very substantial bearings to support the plate when it is in the pick up position as the loading exerted by a large pad is very considerable.

Manufacturers claim as the pad strokes below the base of the machine there is a larger work area. The down side to this is that the machine has to be well guarded because of the back and forwards movement of the plate. Automatic loading can take advantage of the shorter cycle times.

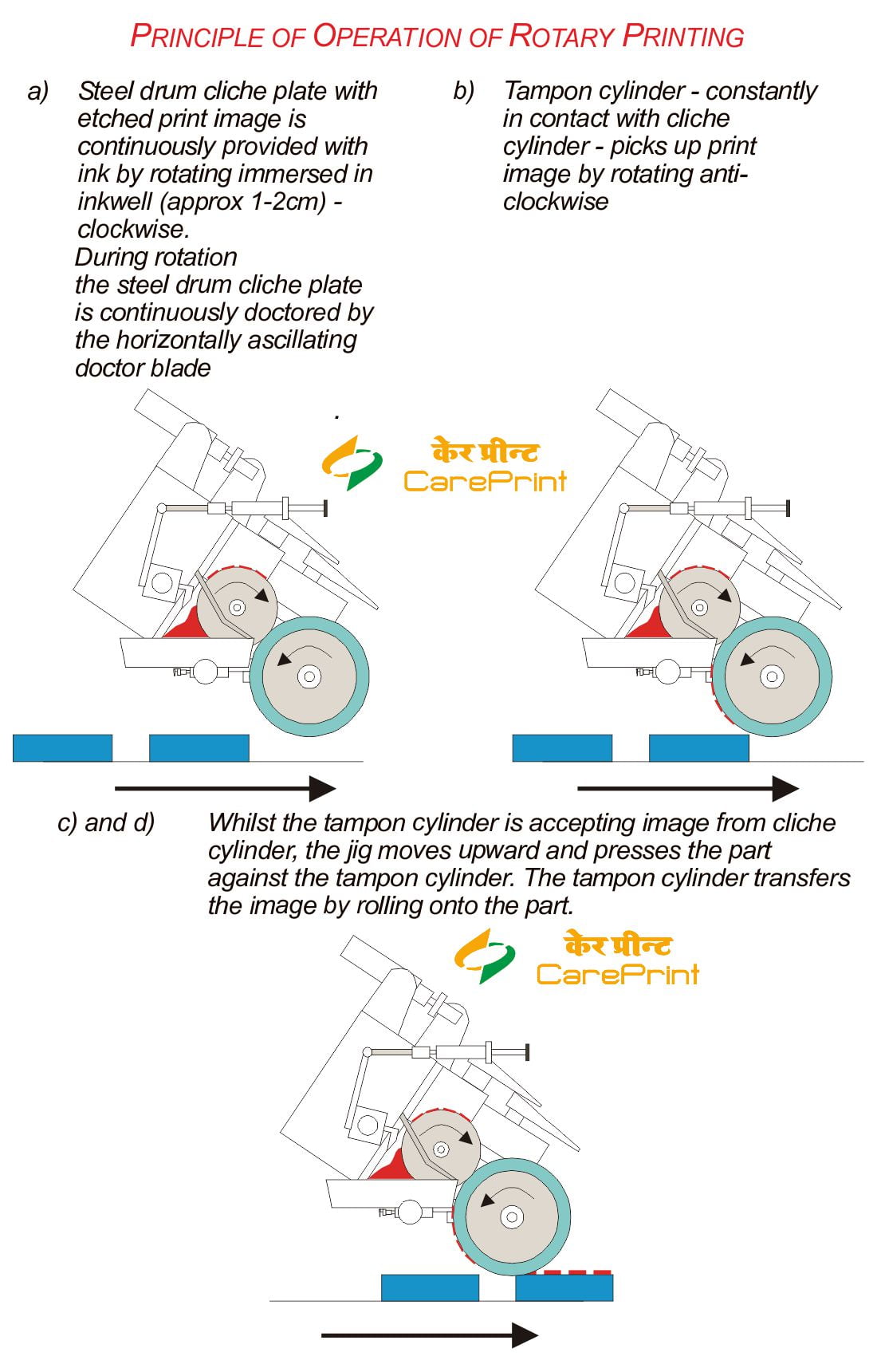

4: ROTARY PAD PRINTING MACHINE

This novel machine is a multicolour pad printing system designed around rotary tables. The system is fully mechanical, operated by cams, which enables up to 750 cycles per hour. Printing 4 colours at 250 per hour is achievable.

The machine is ideal for short runs and medium length runs. The design of the system is such that set up is easy and quick and different pad shapes can be accommodated on the carousel, to suit the design.

The system operates by a combination of two rotating tables and a rotating pad carousel. On one table, the part to be printed is mounted. On the second table, the plates containing the image separations are mounted. These plates can be adjusted in both X, Y and rotary axis allowing accurate positioning of the image. Above the plates there is a system of sealed ink cups, which ink the plate by passing over the image area and returning to the rest position. The plates are inked just prior to the plate being offered to the pad.

The pad picks up the image. The pad carousel and the plate-carrying table then rotate so the pad carrying the image is over the part to be printed, whilst a fresh pad is positioned over the freshly inked second plate. The pad then descends and prints the part. Simultaneously, the fresh pad descends and picks up the image from the second plate.

This sequence continues until the multicolour image has been printed. When the image is complete, the rotary table is indexed. This positions a new part under the pad, while the printed part is removed and replaced with a new, unprinted part. The system allows for the use of photopolymer plates but as with conventional machines steel plates give a longer life.

The Carousel Printer is a very useful tool particularly for sub-contract printing companies who are often faced with shorter runs of multicolour images. For longer runs conventional linear, rotary and oval systems are more economic because of their higher output. .

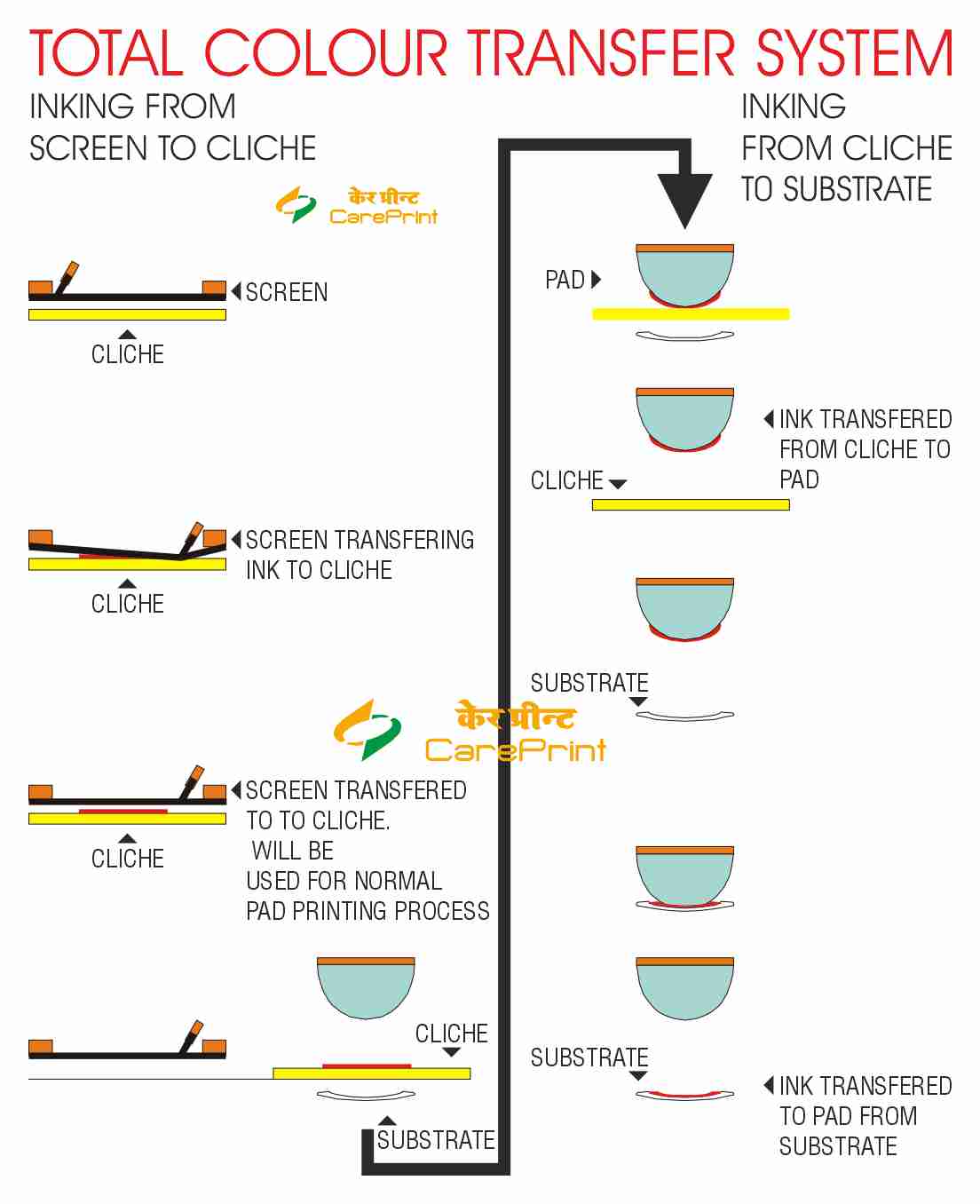

5: TOTAL COLOR TRANSFER SYSTEM

This technique was developed for printing onto ceramic items it uses a mix of Pad Printing technology with Screen Printing methods.

As a general description, the system does not use etched plates as those normally associated with conventional Pad printing. Instead, the ink or ceramic colour is screen printed onto a flat silicone coated plate. The ink does not adhere to this plate, but rests on top.

The screen printed image is then picked up by the pad and transferred by pad onto the item.

When this process was first developed in the 1950′s the colour was cold. This did not allow total transfer of the ink, to meet this need thermoplastic colour was used. This colour is a wax like solid at room temperature. The screen has a metal mesh, which is heated by passing an electric current through it. This raises the temperature of the ink to 75oC causing it to melt and flow with the action of the squeegee like a conventional ink onto the flat silicone surface. This surface is controlled at some 35-40oC lower than the printing ink. The pad lifts the colour from the smooth silicone plate and transfers it to the ceramic item. The item chills the ink and cases a complete transfer.

Although this process is used almost exclusively in the ceramics industry it demonstrates the happy marriage of the two processes.

Some of the advantages are as follows: Patterns can be offset printed on areas and surfaces that cannot be printed by direct Screen Printing. e.g. Double curved surfaces. Fine Lines and heavy bands can be applied at the same time as the principal pattern in one machine pass.

Heavy deposits of colour can be applied to complex shapes. This was previously only possible using Screen printing onto its associated limit of printable shapes.

The Screen process determines the quantity of colour applied. This ensures consistent high quality prints, using a full range of effects from solid lines to half-tones. Many users manufacture screens in house .

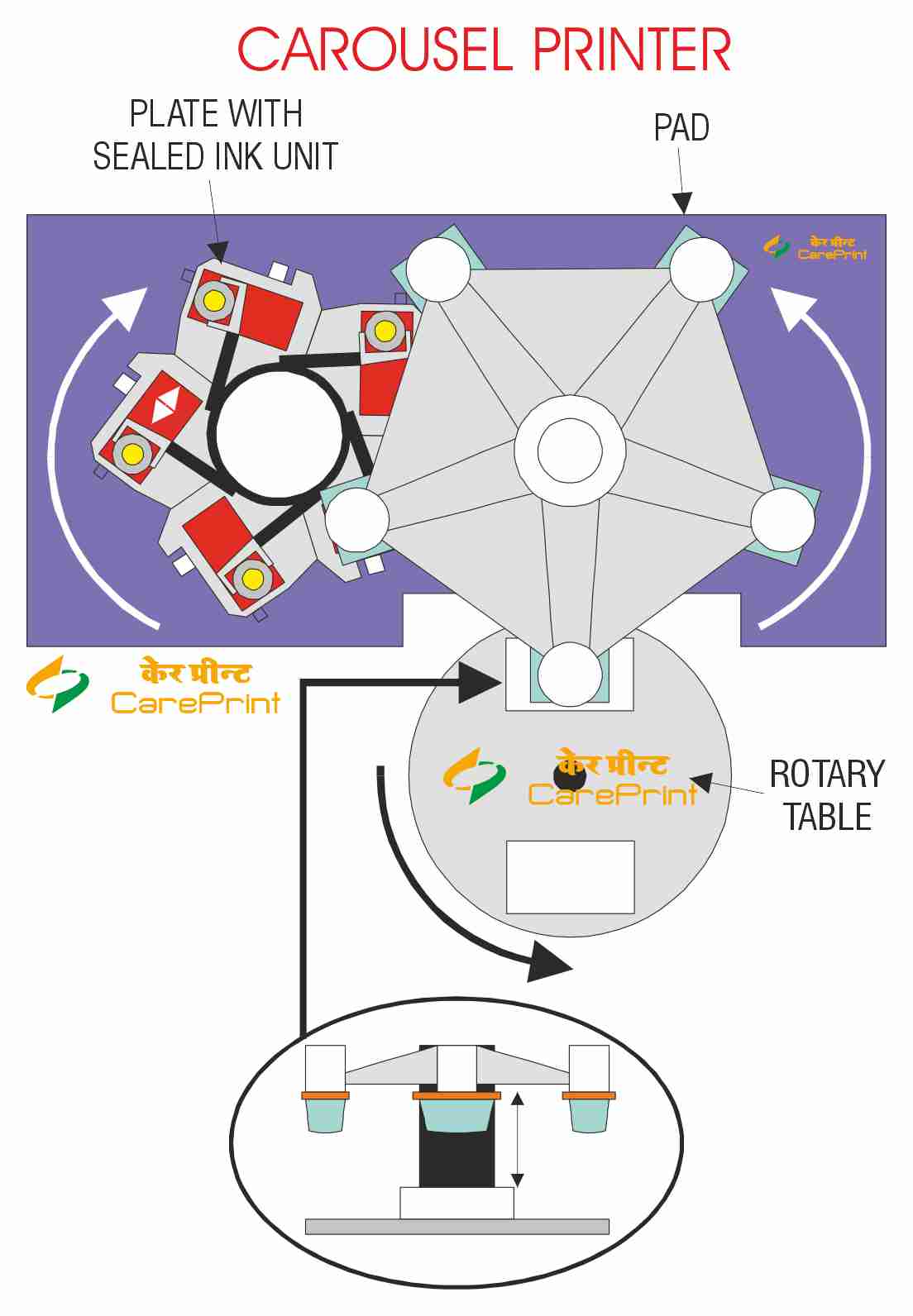

6: CAROUSEL PAD PRINTING MACHINE

This novel machine is a multicolour pad printing system designed around rotary tables. The system is fully mechanical, operated by cams, which enables up to 750 cycles per hour. Printing 4 colours at 250 per hour is achievable.

The machine is ideal for short runs and medium length runs. The design of the system is such that set up is easy and quick and different pad shapes can be accommodated on the carousel, to suit the design.

The system operates by a combination of two rotating tables and a rotating pad carousel. On one table, the part to be printed is mounted. On the second table, the plates containing the image separations are mounted. These plates can be adjusted in both X, Y and rotary axis allowing accurate positioning of the image. Above the plates there is a system of sealed ink cups, which ink the plate by passing over the image area and returning to the rest position. The plates are inked just prior to the plate being offered to the pad.

The pad picks up the image. The pad carousel and the plate-carrying table then rotate so the pad carrying the image is over the part to be printed, whilst a fresh pad is positioned over the freshly inked second plate. The pad then descends and prints the part. Simultaneously, the fresh pad descends and picks up the image from the second plate. This sequence continues until the multicolour image has been printed. When the image is complete, the rotary table is indexed. This positions a new part under the pad, while the printed part is removed and replaced with a new, unprinted part.

The system allows for the use of photopolymer plates but as with conventional machines steel plates give a longer life.

The Carousel Printer is a very useful tool particularly for sub-contract printing companies who are often faced with shorter runs of multicolour images. For longer runs conventional linear, rotary and oval systems are more economic because of their higher output. .

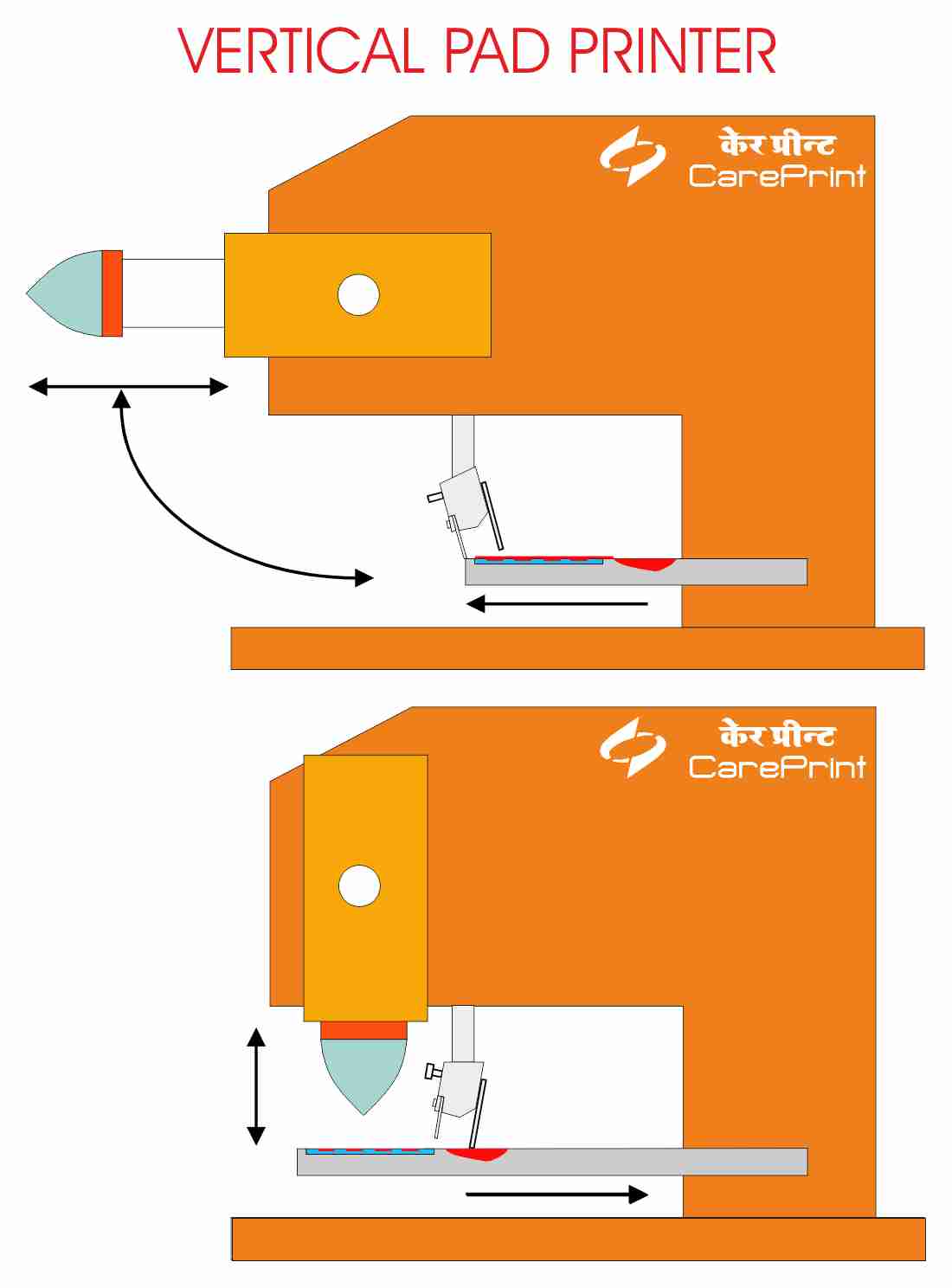

7: VERTICAL PAD PRINTING MACHINE

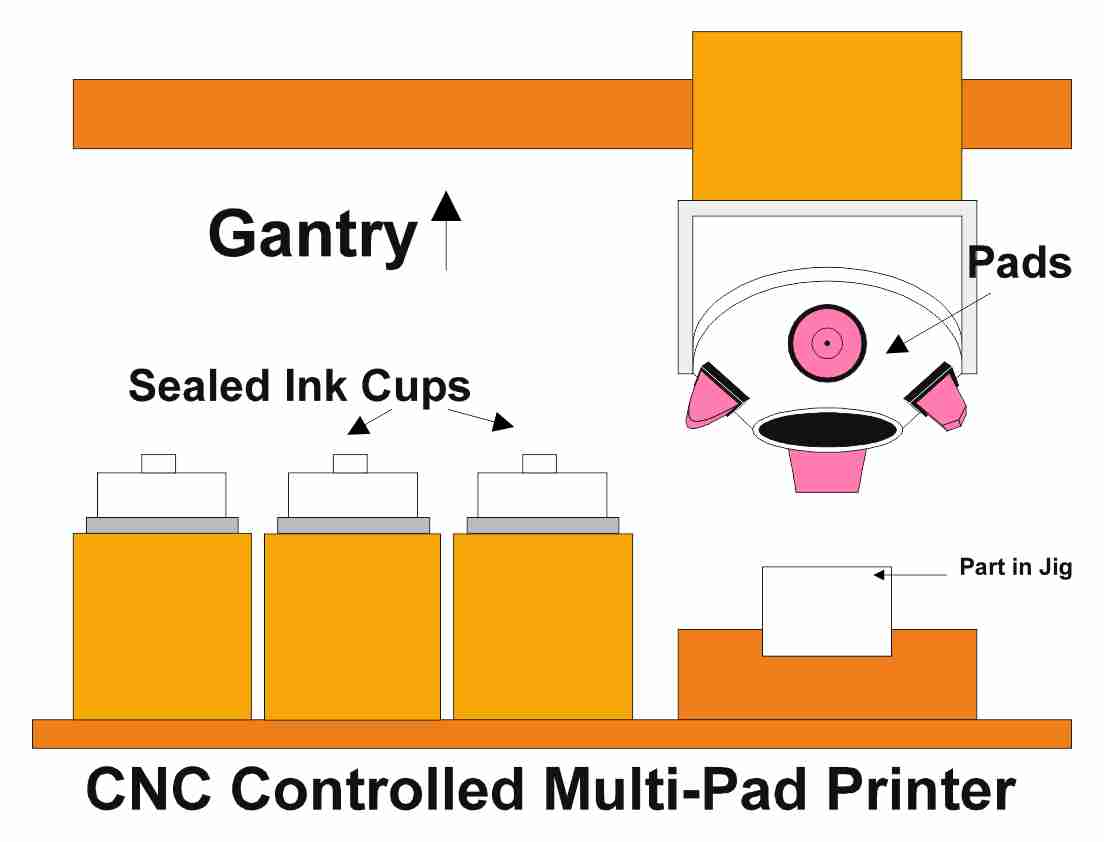

8: CNC PAD PRINTING MACHINE

The use of servo motor drives to all the actuators gives a very smooth, highly controllable print action. Stroke lengths are infinitely variable within their extremities.

Linked into a Programmable Logic Controller this system allows simple setting procedures and enables several set ups to be programmed into the machine. Manufacturers claim considerable energy savings over pneumatically actuated machines and they are not effected by fluctuations in airline pressure. This system of control and actuation is built into standard machines.

Modular machine assemblies can be produced to suit almost any application. An example of such a configuration is shown below. The degree of complexity is only governed by the imagination of the designer and the number of modules he wishes to use. All the elements of component manipulation can be combined with multiple closed cups, pad cleaning, varying pad stroke lengths, alternative pad shapes etc. This system is often used where items have to be printed in line with other assembly processes or more complex multiple prints on different surfaces. The conventional multicolour feed system is inappropriate for this type of work.

This flexibility comes close to producing the ideal machine for a particular application but it is substantially more expensive than a conventional machine. If the workload can justify the increased investment it is well worth considering. Don’t be carried away by the control technology it still must be a capable printer. Print rates will not necessarily be higher but down time and set up should be much reduced. The ability to store and retrieve setting details for the next time a job is run must give more consistent quality. .

Open Inkwell / Closed Cup Machine

Great benefits from Our Printing Pads

Our Pads are produced from best German silicone Companies like Wacker, Dow Corning

Other Manufacturers

Pad Printing 101.

The ultimate Purchase Guide which will advice you on how to Buy, maintain, re-use and safely discard after use our Pad Printing Plates, Silicone Pads, Inks.

Pad Printing Machine Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.

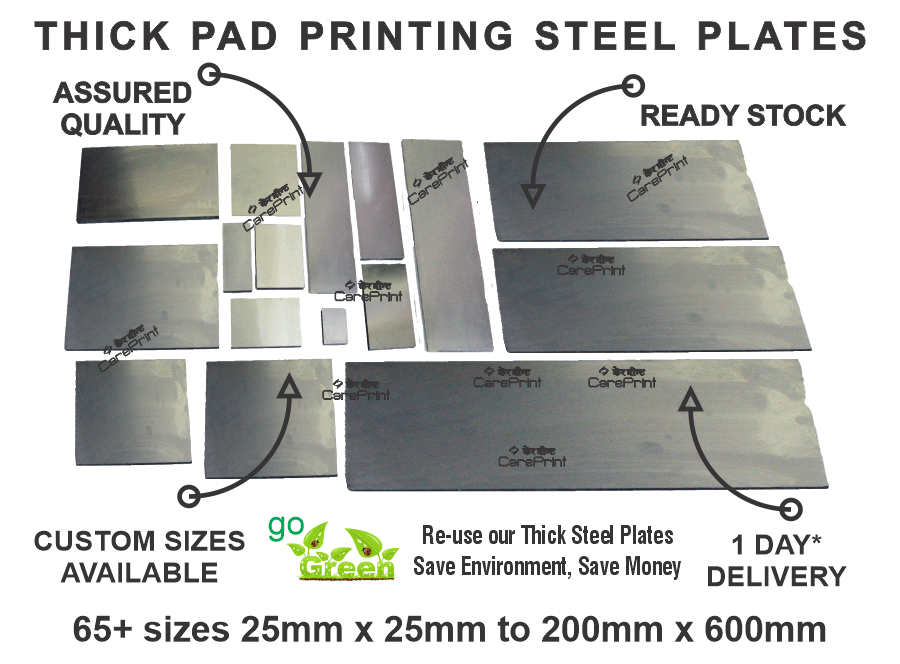

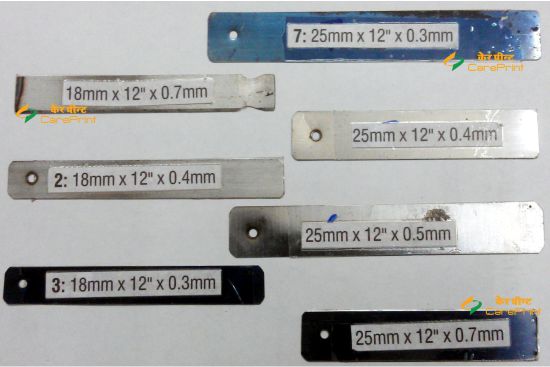

Pad Printing Plate Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.

Pad Printing Silicone Pad Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.

Pad Printing Ink Buy Guide

Curabitur ac leo nunc estibul et mauris vel ante finibus.